Tips for Optimizing Swiss Screw Machining Efficiency

6 29 CST07,2023

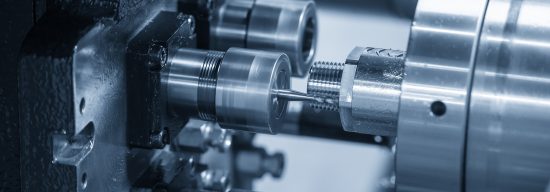

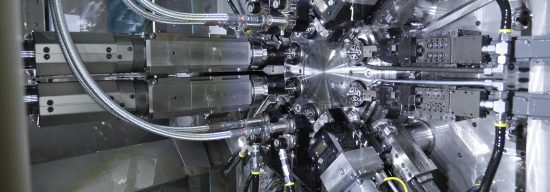

Swiss screw CNC lathes are highly productive machines, but running them at less than maximum efficiency can mean a significant loss of output. This blog explains the kind of precision…