What are Cores in the Sand Casting Process?

The basic concept of the sand casting process is the use of a mold to create the cast part. The mold contains a negative impression of the part as the molten metal will be poured into it. To create the mold, a pattern will be used. The pattern helps to design the exterior walls of the mold. Yet many parts are designed to create complex interiors where there may be spaces where the molten metal should not enter.

For example, there may be a part with an interior hole that will be used to slide the part into a complex assembly system. A rod will go through the hole to hold the part into place. To create this area, cores will be used during the casting process.

What is a Core?

A core is an insert that will be placed into the mold. The sand is poured over the pattern while being compacted and pressed. The core’s purpose is to direct where the molten metal will go to fill the cavity in the mold. Some cores can be very intricate. They may have interior angles and geometries to create complex holes and passages for the molten metal. They may also be solid to create interior cavities, or hollow where the core will allow the metal to fill other sections.

What are Cores Made From?

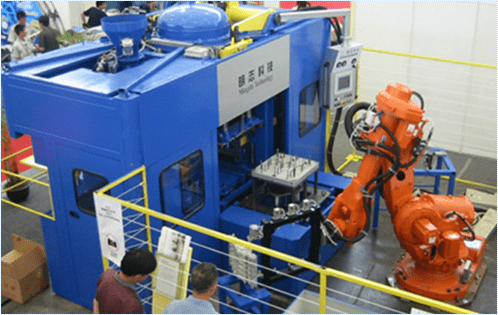

Cores will be made from the same resin sand used in the casting process. The sand is placed into a core box that has the desired interior pattern for the part. The sand will be hammered, heated, or blown into the core box depending on the manufacturer’s capabilities and equipment. Then the core will be removed from the core box and positioned into the mold.

Cores can be made using hot box and cold box methods. The hot box method is when the resin is added to the sand and a catalyst is used. The catalyst is activated using heat as the core hardens. The cold box method involves using a catalyst that does not require heat to be activated as the resin and sand hardens to create the core.

The reason that cores are made from the same resin sand as the mold is because the sand can stand up to the temperatures of the molten metal without damage. Once the metal cools, the mold will be broken apart. To remove the core inside the solid metal, machines will perform a shake-out process that vibrates the part while breaking apart the sand. A hole is typically let in the mold to allow the sand to be shaken and poured out. This hole may be later sealed during the finishing process if it is not desired for the finished part.

How are Cores Held into Place?

Since the core will be inside the mold while the molten metal is poured into it, it will shift or rise from its designated place. Chaplets are made from similar metal that will be used to create the cast part. This metal will hold the cores in place until the metal is poured inside. The chaplets that touch the molten metal will become part of the actual component when the metal cools. Then the core will be shaken apart and removed.

Another way to hold the core into place is to make the core longer than the mold itself. These instances are used when the space that will not fill with metal will reach past the exterior wall of the mold. Divots placed into the sand mold will hold the core in place.

For more information about creating cores for your sand casted parts, contact Impro.