What is Precision Machining Technology?

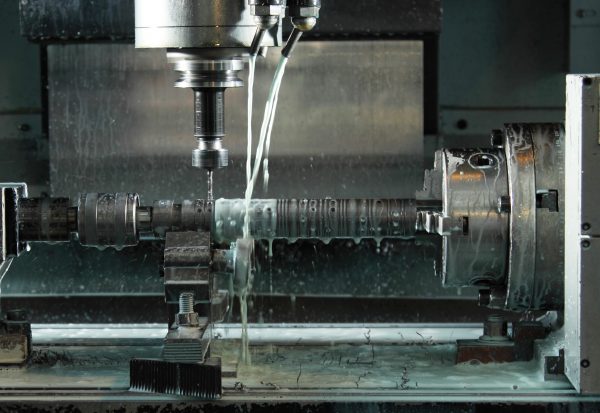

When creating parts for applications, companies may use precision machining as their manufacturing method. Precision machining processes involve using cutting, turning, milling, grinding, sawing, and boring tools to remove specific amounts of materials from a base material piece until the part is made. This manufacturing method faces unique challenges in producing highly accurate parts in extremely intricate and geometrically complex shapes. To adhere to a customer’s specifications, different precision machining technology is used.

What is Precision Machining Technology?

At one time, this manufacturing method solely relied on manual tools used by operators. These highly skilled professionals would perform countless calculations, measurements, and set-up of the equipment to form the part to the appropriate dimensions. Each piece of equipment needed its own technician to operate the machine. While the technicians could turn around thousands of parts in batches, the probability of parts needing to be scrapped due to inaccuracy was also present.

As technology advanced, precision machining equipment came with computer numeric controls (CNC). The CNC process uses automated software that comes with predefined functions. These predefined functions and motions are fed to the machine through the prepared program that controls the manufacturing task. The technology specifies the machine’s speed, depth of cut, feed rate, rotation of tools, tool attachments and workpiece beds, as well as other aspects. This program performs the calculations quickly and accurately based on inputted data, as the computations are automatic.

Technology Types

Computer-aided design (CAD) and computer-aided manufacturing (CAM) are the two most common types of software used with CNC machining processes. A precision machining tool may have CAD software or a combination of CAD/CAM applications.

- CAD: A visual model is created from the part’s available specifications and data. Then changes may be made more effortlessly to achieve a higher level of accuracy before the manufacturing process begins.

- CAM: Software prepares an CAD model for the machining process by checking accuracy and creating a toolpath. The CAM software will set all machine parameters (cutting speed, cut height and other factors) as well as the orientation of the part.

Advantages of Precision Machining Technology

Precision machining technology allows a manufacturer to boost their efficiency and accuracy capabilities for the part. This technology allows for fewer machine operators to use the system, so the remaining technicians can perform other tasks. Often, a company will use both manual and CNC machines in processes based on the project to provide the best set of advantages to the customers.

Also, a customer finds a range of cost savings with precision machining technology. This technology ensures repeatability for parts in low and high volume batches. It reduces the amount of poor quality parts that become scrapped because of the wrong dimensions and specifications.

For more information about our precision machining technology, contact Impro.