When to Select Investment Casting for Components

Selecting the appropriate precision casting and machining company to make components relies on understanding the needs of the application, your budget, and your time to market deadlines. Another important factor depends on the type of production process that will be required. You may select from investment casting, sand casting, CNC precision machining and other processes. When debating whether investment casting is right for your components, take these factors into consideration.

Prototype, Low to High Volume Production

Investment casting involves creating a wax pattern of the component and building a ceramic shell around the wax pattern to make a mold. Then the wax is melted from the mold and molten metal is poured into it to create the part. Investment casting is repeatable as the process is designed to run consistently to make a certain volume of parts. Investment casting is ideal for production runs regardless of volumes. While it could be used to make a prototype, other cost-effective measures may be chosen if you are looking to make only one component for a single time.

Quality Consistency

Since the wax pattern will be the exact replica of the metal component when it is created, investment casting is often used when you need design consistency. This benefit is especially important for parts that can be used in varying applications and industries. The metal component needs to have the same dimensions, geometries and intricacies whether you are making low to high volumes. With investment casting, that dimensional accuracy can be maintained for every casted mold and metal product.

Range of Different Metals

Another advantage to selecting investment casting for the creation of components is that you are not limited by what base metals or metal alloys that can be used. The ceramic molds can handle the melting temperatures and molten characteristics of a wide selection of metals. If the part needs to be made from copper, steel, titanium or a specialty alloy, investment casting processes can typically handle the production process. Both ferrous and nonferrous metals work well with this process.

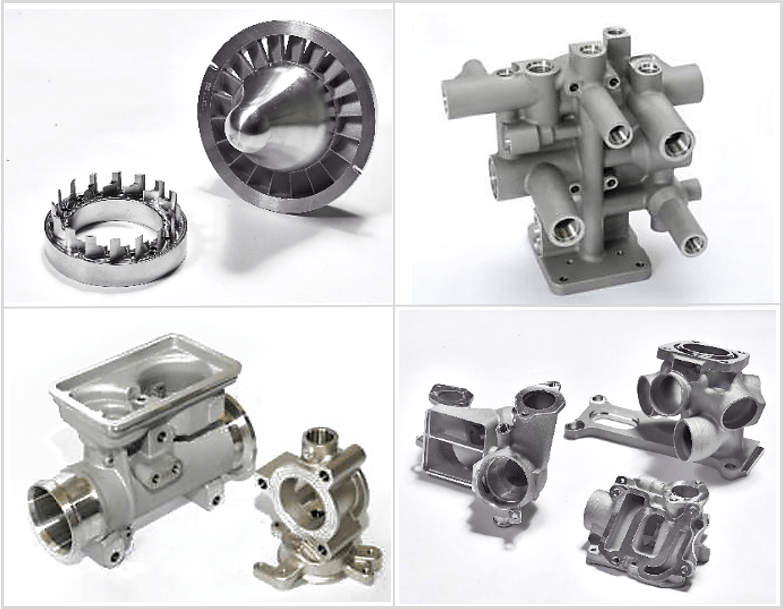

Intricate Internal Parts

Investment casting allows for cores to be placed into the pattern before the ceramic shell is formed to create the mold. Then the cores along with the pattern can be removed before the molten metal is poured inside. This process allows for parts to have complex and intricate internal parts that are required for the application.

Lower Tooling Costs

Costs play a major factor when selecting casting and machining processes. If you are looking to make a large quantity of parts with high precision that does not need a lot of tooling, then investment casting is a solid choice. Precise dimensions and tight tolerances can be reached with this process as the investment castings are created to net shape. You also save on material and processing costs as only the right amount of metal is poured into the mold.

Learn more About Our Process

When deciding on the right precision machining and casting process, it is always ideal to talk with an investment casting expert to discuss your application. Speak with Impro to learn more about this process and how it can help you create the parts that you need. Contact us today to get started.