Blog

Troubleshooting Common Issues in Sand Casting

July 11th, 2024

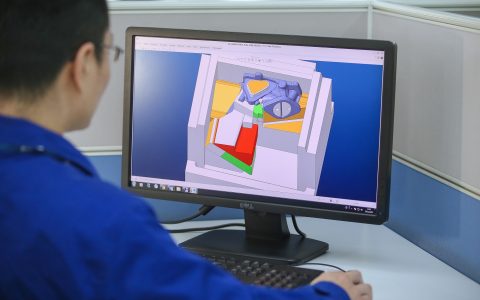

From Design to Reality: The Journey of a Cast Metal Part

June 3rd, 2024

From Sand to Solid: A Step-by-Step Journey through the Sand Casting Process

February 5th, 2024

Advantages of Sand Casting for Exhaust Manifolds

November 7th, 2023

An Introduction to Sand Casting Exhaust Manifolds

June 27th, 2023

An Introduction to Sand Cast Iron Engine Blocks

June 20th, 2023

Sand Casting for Power Generation Equipment Applications

June 13th, 2023